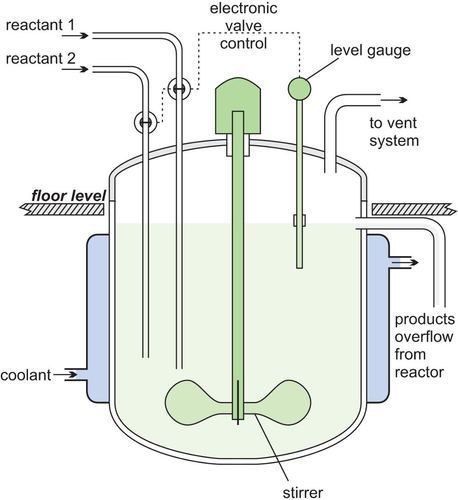

Continuous Stirred Tank Reactor CSTR

UD Technologies are Leading manufacturers and exporters of Glass Continuous Stirred Tank Reactor- CSTR from Vadodara, Gujarat, India.

We manufacture Glass Reactor with the highest quality standards of workmanship and material.

The Reactor is a vessel or system in which chemical Reaction proceeds and Reactants converts in Production. Design of Chemical Reactor Varies Widely with process Parameters.

Due to transparency and Universal Corrosion resistance; Chemist s and Process Engineers prefers Borosilicate Glass for Kilolab, Pilot plants, and Production for small batches.

Glass CSTR is the most basic type of continuous reactor having wide application in various types of chemical process industries. These reactors are open systems, where the raw materials and Products are free to enter or exit the system that operates on a steady-state basis.

In Continuous Stirred Tank Reactor – CSTR, the conditions in the reactor don’t change with time. Reactants continuously introduce into the reactor, while products continuously remove from CSTR. They are very well mixed, so the contents have relatively uniform properties such as temperature, density, etc. throughout. Also, conditions in the reactor’s exit stream are the same as those inside the tank.

Continuous Stirred Tank Reactors are used in performing various Exothermic, Isothermal or Endothermic reactions like Homogeneous Liquid Phase reaction. CSTR is also used as a loop reactor in the API Industry. A jacket or similar arrangements like bath can be provided to remove or supply heat

Multiple Continuous Stirred Tank Reactor – CSTR is adopted when 1.the reaction is too slow and 2. two immiscible liquids or viscous liquids are present and require a high agitation rate 3. High Conversion of reactant needed

For flow chemistry, Continuous stirred tank reactors – CSTR are often used in cascades of 3 or 4 CSTRs. By adopting this configuration of multiple CSTRs the residence time control can be much improved and the back mixing significantly reduced.

UD Technologies offers Continuous Stirred Tank Reactor with Automation

Please also visit for more detail about our products

Glass Continuous Stirred Reactor