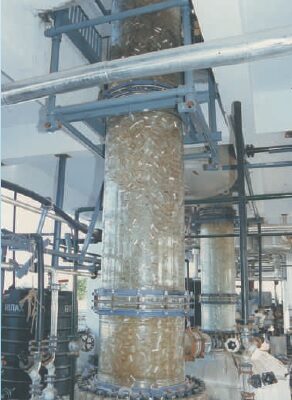

Distillation assembly over Glass Lined Reactor

Different Options for Distillation Set up over Glass lined Reactor

Different Options are available considering Process requirements

- Simple Distillation

- Fractional Distillation

- Azeotropic Distillation

- Different improved packings considering Pressure Drop and Process conditions

- Continuous distillation-GLR Shall be used as Reboiler

Please contact our technical person at [email protected] to freeze your requirements

Glass Distillation setup over Glass Lined Reactor may change with process requirements like

1. Batch /Continuous

2. Size of GLR

3. The requirement of Azeotropic distillation

4. Site constraints

5. Process Requirements

6. Instrumentation and Automation requirements

For, Offer for Distillation assembly over GLR

Please submit the following details

1. GLR Size

2. Available total height area

3. Operating Pressure 4. Application: GMP/Non-GMP 5. Heat transfer area of Condenser

Please also visit for details

http://udtechnologies.com/industrial-glass-equipment/glass-shell-and-tube-heat-exchanger/

Estimation of Heat Transfer area of Condenser for Glass Lined Reactor in Batch Distillation

http://udtechnologies.com/mineral-acid-treatment/hydrogen-chloride-gas-absorber/

How to reduce Solvent losses during Batch Distillation

Accessories and Instrumentation for Glass-:lined equipment

#GLR #assemblyoverGLR #distillation #maharastra #rajasthan #MP #mumbai #chennai #udaipur #vapi #hyderabad

[/vc_column_text]