Bromine recovery Plant

UD technologies are manufacturers, Suppliers, and Exporters of Bromine Recovery Plant from Industrial Bromide Solution.

Bromine is a highly reactive material finds wide applications in many Chemical Industries like Organic Intermediates, Dyestuffs, Agrochemical, Fire retardants, etc for bromination

The reactions to form the chemicals usually generate hydrogen bromide as a by-product as in the following reaction:

R – H + Br2 –> R – Br + HBr

Clearly, no more than half the bromine added ends up in the product. The rest liberates as Bromides. Bromides are Hydrogen bromide gas-HBr and as dissolved bromides such as Sodium Bromide-NaBr, Potassium Bromide-KBr.

As bromine is an expensive raw material and economic good sense suggests that it should be recovered. Hydrogen bromide dissolves in water and Bromine can be recovered from this solution. Similarly, Bromine recovery is possible from other aqueous waste streams. We can then purify the bromine to give a product (typically better than 99.5% bromine) to re-use in the reactors.

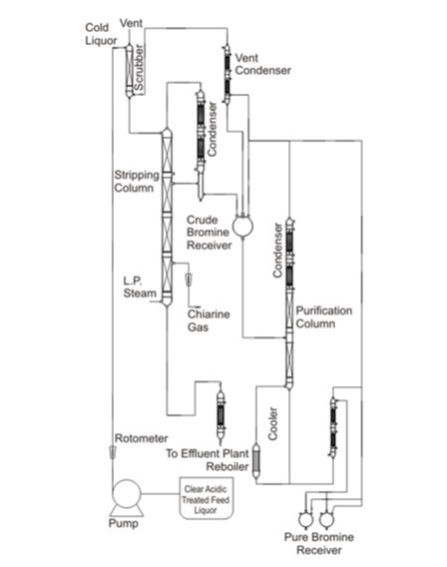

Chlorine Gas oxidises aqueous Bromide solution in the Stripping column. The Chlorine liberates elemental bromine from the dissolved bromide. Live steam removes out bromine and excess chlorine from the Stripping column. Bromine vapors condense in the Glass Heat exchanger to liquid.

Purification column distills Crude bromine to the purity of a minimum of 99.5%. The solution is not always so simple though, as feeds are often contaminated with organic material from process. These organic impurities have to be removed by pre-treatment before feeding to the plant.

Bromine recovery plant and technology is very tricky and requires Expertise.UD Technologies provides technology and Plant

Bromine Recovery Plant System

The system consists of

Stripping / Reaction Column – Glass

Cooling / Chilling Heat Exchangers

Phase Separator – Glass

Bromine Purification Column

Pure Bromine Condenser – Glass

Vent / Guard Condenser – Glass

Bromine Reboiler – Glass

Bromine Product Cooler – Glass

Crude / Pure Bromine Collecting Receiver – Glass

Salient Features

- Bromine Quality offered as per IS Quality and Dry Bromine (Optional)

- Energy Efficient Process and Smooth Production process which reduces Ownership cost

- More Efficient Process

- Plant Design considering safety

- Plant design is such that minimum Instrumentation is required

- Can offer PLC Controlled Plant

- We offer different Material of Construction Options Like Glass Lined /PVDF –Wherever, Tantalum Possible

Properties of Bromine :(Collected from Reliable Sources)

| Name: | BROMINE | |

| CAS No.: | 7726-95-6 | |

| Mol. Wt.: | 159.808 | |

| Melting Pt.: | 266 | K |

| Boiling Pt.: | 331.9 | K |

| Density (293K): |

3.119 | g/cc |

| Hf°: | 0 | Kcal/mol |

| Gf°: | 0 | Kcal/mol |

| Hvap: | 7210 | cal/mol |

Please also visit the Bromine Production Plant from Sea Bittern

and Updates