Anhydrous HCL Gas Generator by Boiling route

UD Technologies are Leading Manufacturers, suppliers, and Exporters of Dry HCL gas generator by Boiling Route

HCl Gas Generator produces Hydrogen Chloride Gas which uses in Hydro-chlorination reaction to attach HCl Molecule to form Water-soluble Hydrochloride salts.HCL Gas is also used to make IPA-HCl or Methanol-HCl. Sometimes it is used to Burn Out fibers above seeds

Generally, for Lab scale, Hydrogen Chloride gas makes available through cylinders. But for industrial production, it becomes very costly.

UD Technologies offer Dry HCl gas generator plant from 10 kg/hr to 300 Kg/hr. The Boiling route is the most cost-effective route both Fixed capital and working capital where 30% of Hydrochloric Acid is used in-house.

UD Technologies supplied HCl Gas Generator with Boiling Route with different capacities from 40 to 60 Kg per Hour successfully. Lower and Higher capacities are available.

Principle:

Hydrochloric acid forms azeotrope at 20-21 %.So while boiling 30-33% Hydrochloric acid, the remaining 9% HCl converted HCl gas.HCL Gas Evolved with water vapor which is cut down at five different stages like different condensers with Cooling water-Chilled Water –Brine and Sulfuric Washing to have Dry Gas

The system looks simple but to pass HCl Gas during the reaction in Reactor, a number of factors during design to be considered to have smooth and operator-friendly plant

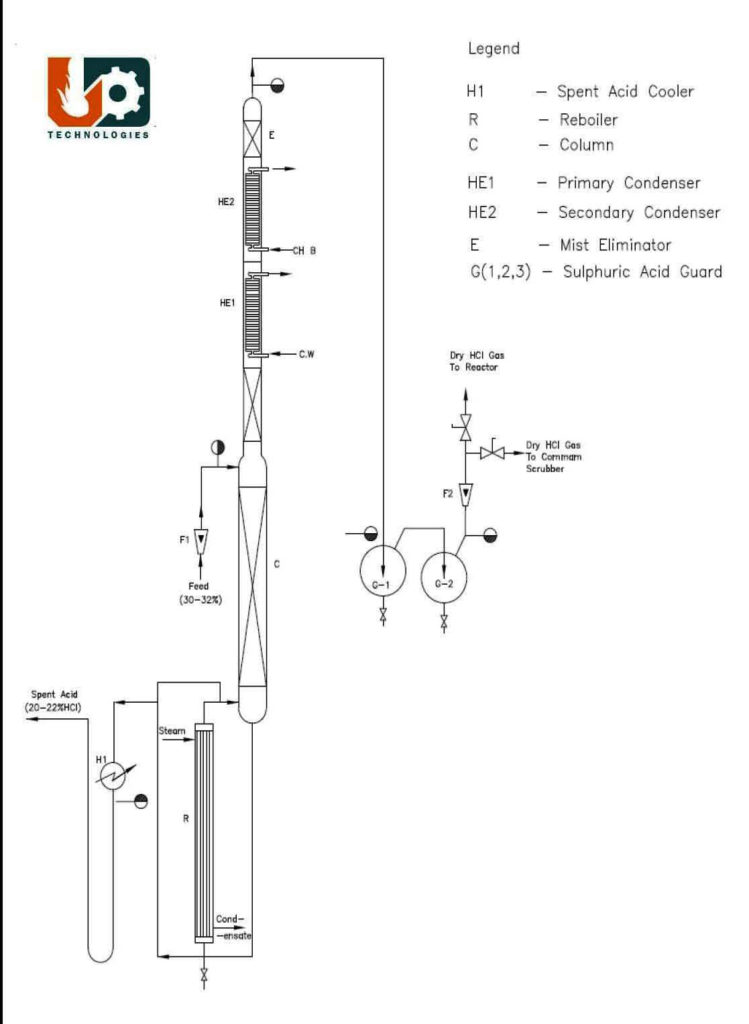

Process Flow Diagram for Anhydrous HCl gas Generator by boiling route

Process Description:

The plant is designed for the production of Dry HCL-Gas by the process of Azeotropic distillation of 30% Hydrochloric Acid Solution. The pre–heated [optional] feed i.e. 30% Hydrochloric Acid Solution generally heated by the bottom overflow effluent (20% Hydrochloric Acid) and fed to the distillation column by a pump whereby the rate of feed flow is controlled. The feed is heated through a shell and tube-type thermo-siphon re-boiler where the heat energy is supplied by steam. The Bottom product ( effluent ) is a 20% HCL- solution, which gets cooled by cold 30% HCL-solution prior to discharge for storage. The top product HCL-Gas is dried in the Drying unit using a dehydrating agent. The moisture content in the gas is expected to be ≤ 0.01% depending on the efficacy of dehydrating agents.

The plant has been designed to operate as a continuous process and is the system is quite stable as all the wetted parts are from Borosilicate 3.3 Glass and PTFE and Impervious Graphite

Salient Features

- Simple Operator friendly Plant

- No H2 SO4 required in the process as feed

- 20%HCL can be used inhouse

- Designed so that Gas shall pass directly in Large GLR even up to 6.3KL.No compressor needed

- Design compactness

- Low capital and operating costs

Typical Indicative consumption figures for Kg of Dry HCl Gas Plant

| 30-32% HCl | 8.5 |

| 98% Sulfuric Acid | Nominal |

| Cooling Water at + 300C(M3/Hr) and 50C Temp. Difference | 3 |

| Chilled Water -5 degc (M3/Hr) | 3 |

| Steam -2.5 Kg/cm2 G | 1 |

| Brine,-10, (M3/Hr) | 1.5 |

| Spent acid (kg/hr) | 7.5 |

The above figures are indicative and may vary from plant to plant

Please send the following details to [email protected] to have a quote

- The Capacity of HCL Gas Generator in terms of HCL Gas, Kg/hr

2. Glass Lined Reactor Size, possibly Drawing

3. Available Utilities like steam, Cooling water, Chilled water, and Brine

Further please click on the following links

Glass Lined Reactor -Accessories and Instrumentation

Hydrogen Chloride Gas Absorber

https://www.linkedin.com/pulse/anhydrous-hcl-gas-generation-calcium-chloride-route-samir-shah/