Gas Absorber and Wet Scrubber

UD Technologies design, Manufacturer and commission Gas Absorber or Fume Scrubbers or wet scrubbers for Gases like

- Hydrogen Chloride

- Hydrogen Chloride and Chlorine

- Hydrogen Chloride and Sulfur Dioxide

- Chlorine

- Sulfur Dioxide

- Hydrogen Bromide

- Bromine

- Ammonia

- And Others

In Chemical Industries, Gas Absorbers are Essential equipment to control Gaseous Pollution to Environment.

Gas evolves in cases like ..

Produces like HCl, SO2 in Reactions Like Chlorination with Chlorine and Thionyl Chloride, In Bromination reactions, HBr may generate.

Liquid Gas Reactions -In Which Unscubbed Gases like Chlorine, Hydrogen Chloride, Bromine, Hydrogen Bromide

Vent gases of Storage tanks

NOx gases also generate in the reaction using Nitric Acid

Gas Absorbers generally designed with two types

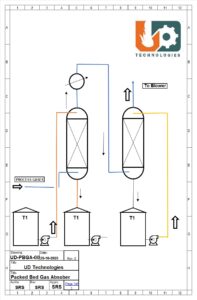

1.Packed Bed Column Absorber

2. Falling Film Absorber

Packed Bed Column Absorber:

Gas absorbers are used to remove contaminants from gas streams, such as flue gas from an exhaust ,from reactor exit .

A gas absorber uses a column often containing random or structured packing

material. Packed bed absorbers utilize gas and liquid streams which flow

counter current to each other. The contaminant gas absorbs into the liquid

stream, resulting in reduced contaminant in the exit gas. The absorption

process depends heavily on the operating parameters, which must be studied in

order to optimize the process.

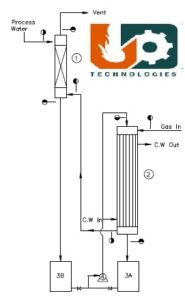

Falling Film Absorber:

Gases like HCl or HBr concurrently flows with

Water inside Tubes of Vertical Shell and Tube Heat Exchangers in Laminar Flow.

As a result,Heat evolves during Absorption is simultaneously removes by cooling water. Due to this phenomena, it results in better absorption of gases and more concentration. For example, Hydrogen chloride strength can be produced 30% with cooling water in Falling Film Absorber and In Packed Bed Scrubber,it produces as 25%.

However, Process design may be different in different reactions and Process Conditions. Some times Packed bed and Falling FIlm absorber are used in series.

Please provide the following details to

- Incoming Gas Flow rate analysis -Component wise in Kg per Hour Maximum -Normal-Minimum

- The temperature of incoming Gas

- Please tell about Organic Impurities if any

For Our Products related Hydrogen Chloride, Please visit

HCL Gas Generator by Calcium Chloride Route