HCl Gas Generator by Sulfuric Acid Route is simple to operate and has lower Utility costs than the other commercially available processes and generates more than 99% HCl from 30% Hydrochloric Acid

Process Description:

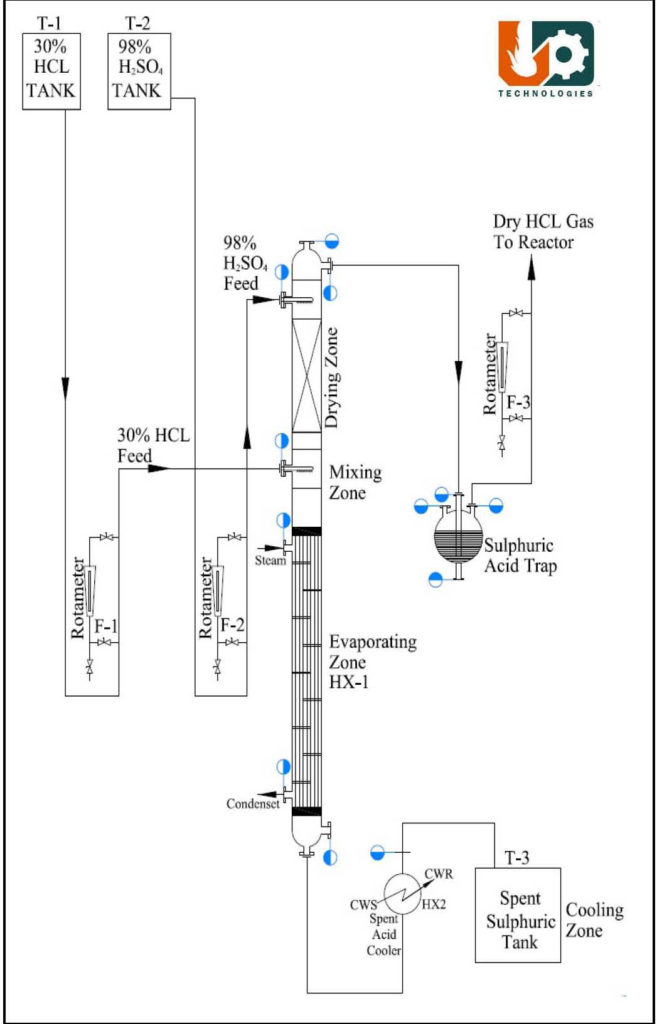

Measured quantities of 98% sulfuric acid and 30% Hydrochloric Acid were added into Mixing Zone to give controlled flow in the Mixing Zone.

Due to mixing with sulfuric acid; HCl gas from the solution strips out by the action of sulfuric acid. Evaporation required heat supplies by firstly, dilution of 98% sulfuric acid and secondly little steam in Evaporating Zone.

Further, HCl gas passes through the Drying Zone. Here, HCl Gas enriches by drying through Sulfuric Acid. For more dryness, HCl Gas passes to the sulfuric acid trap. After that, the dry product gas takes to processor storage.

The bottom product (spent acid) contains dilute hot sulfuric acid. So, the bottom product cools in the cooling zone and reaches the spent acid storage tank. The design of the system is such that the Minimum quantity of HCl gets dissolved in spent sulfuric acid

To remove Dissolved Hydrochloride gas from Spent Sulfuric Acid to a minimum, heat supplies by steam. Slight Steam requires keeping it at a higher temperature. As an effect, the least Solubility of HCl achieves in Sulfuric Acid

SALIENT FEATURES :

- Nearly 100%HCl generated as HCl Gas

- The only utility requirement for this system is cooling water and little quantity of steam

- Very little HCL Gas in spent sulfuric Acid makes it salable

- Smooth and simple operation

- These route units are available up to 75 kg/hr. If you require a larger capacity; please inform

Please also visit the following links for the Boiling route

HCL Gas Generation By Boiling Route