Anhydrous HCL Gas generation unit

UD Technologies is a leading manufacturer,Supplier and Exporter of Anhydrous HCL Gas generation ( from Hydrochloric Acid) unit in Vadodara,Gujarat,India.

Dry HCl Gas Generator produces Hydrogen Chloride Gas from Hydrochloric acid.

Hydrogen Chloride Gas is used in

- Hydro-chlorination reaction. This reaction uses HCl to Organic chemicals to form Water soluble Hydrogen chloride salts.

- Hydro-chlorination of Rubber

- Production of vinyl and alkyl chlorides

- In the semiconductor industry, it is used to both etch semiconductor crystals

Generally, for the Lab scale, Hydrogen Chloride gas makes available through cylinders. But for industrial production, it becomes very costly.In addition, during passing in the reactor; the chemist faces Operating problems

UD Technologies offer Dry HCl gas generator from 10 kg/hr to 300 Kg/hr

With assistance from highly qualified and experienced professionals, UD Technologies manufacture and supply a huge range of Anhydrous HCl Gas Generation Unit.

Our units are recognized for their indispensable features.

Due to wide demand in numerous industries, Our team designs HCl gas generator systems using superior quality materials and cutting-edge technology.

Further, Our quality inspectors strictly inspect the HCl gas generator system.

This unit also has use in the production of IPA HCl and Methanol-HCl for API Industries

Considering capacity; UD technologies offer three different routes.

- By Sulfuric Acid route

- By Boiling route

- By Calcium Chloride route

One can choose a Dry HCl Gas generator through various routes depending on size, Effluent like 21% HCl reusability,cost, and Strictly near zero effluents

A similar Unit is also used for HCl Concentration for Feed HCl above Azeotropic Point

HCL Gas Properties- CAS No.-7647-01-0

| Molecular Weight,kg/kmole | 36.461 |

| Melting Point,K | 159 |

| Boiling Point,K | 188.1 |

| Density (188.1K),kg/M3 | 1.193 |

| Dipole Moment: | 1.1 |

| Hf° | -22.06 |

| Gf° | -22.77 |

| Hvap, kcal/kmol | 3860 |

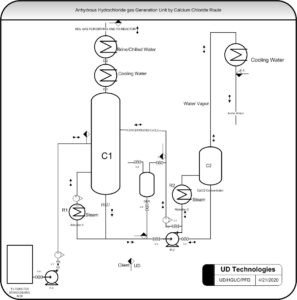

Dry HCL Gas Generation Unit by Calcium Chloride Route

Hydrochloride gas is useful for Several Applications such as hydrochlorination of the Bulk drug to make the product water soluble.

It also requires the anhydrous state for critical reactions where moisture cannot be tolerated.

Calcium chloride route has the cheapest in working cost due to little neutralization cost. Whereas in other routes, a large amount of acid generates whose neutralization cost and handling cost is much more

UD Technologies are Leading manufacturer and supplier for HCL Gas Generation systems by Calcium chloride route

Principle:

Hydrochloric acid and water form a maximum boiling point azeotrope at 11O°C corresponding to a concentration of 20.24%; HCl.

By adding concentrated calcium chloride solution to commercial hydrochloric acid; azeotrope point is eliminated. As a result, the entire HCl becomes available for liberation by distillation.

HCl gas generation through Calcium Chloride Route is the most environmentally friendly technique .

PROCESS DESCRIPTION:

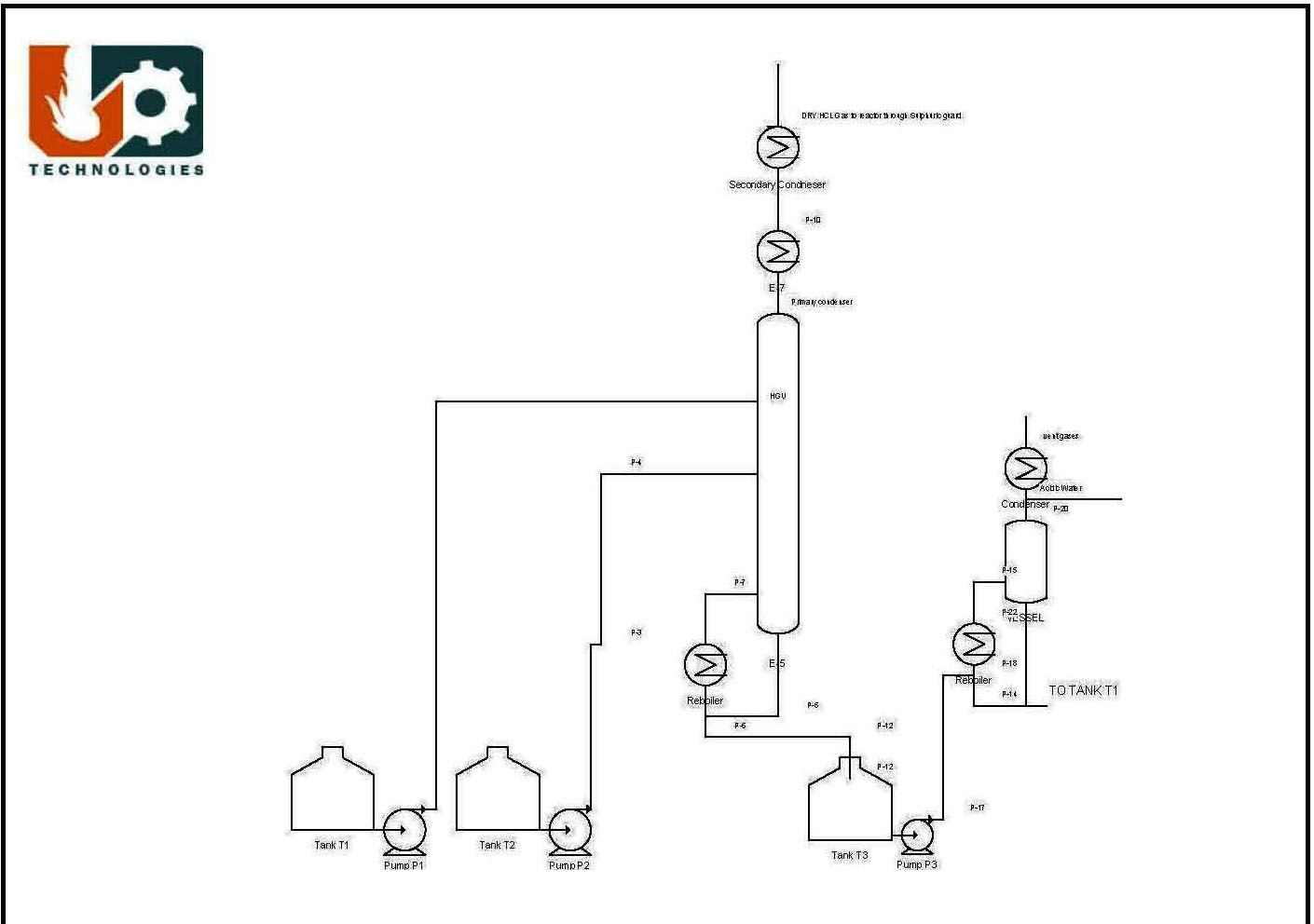

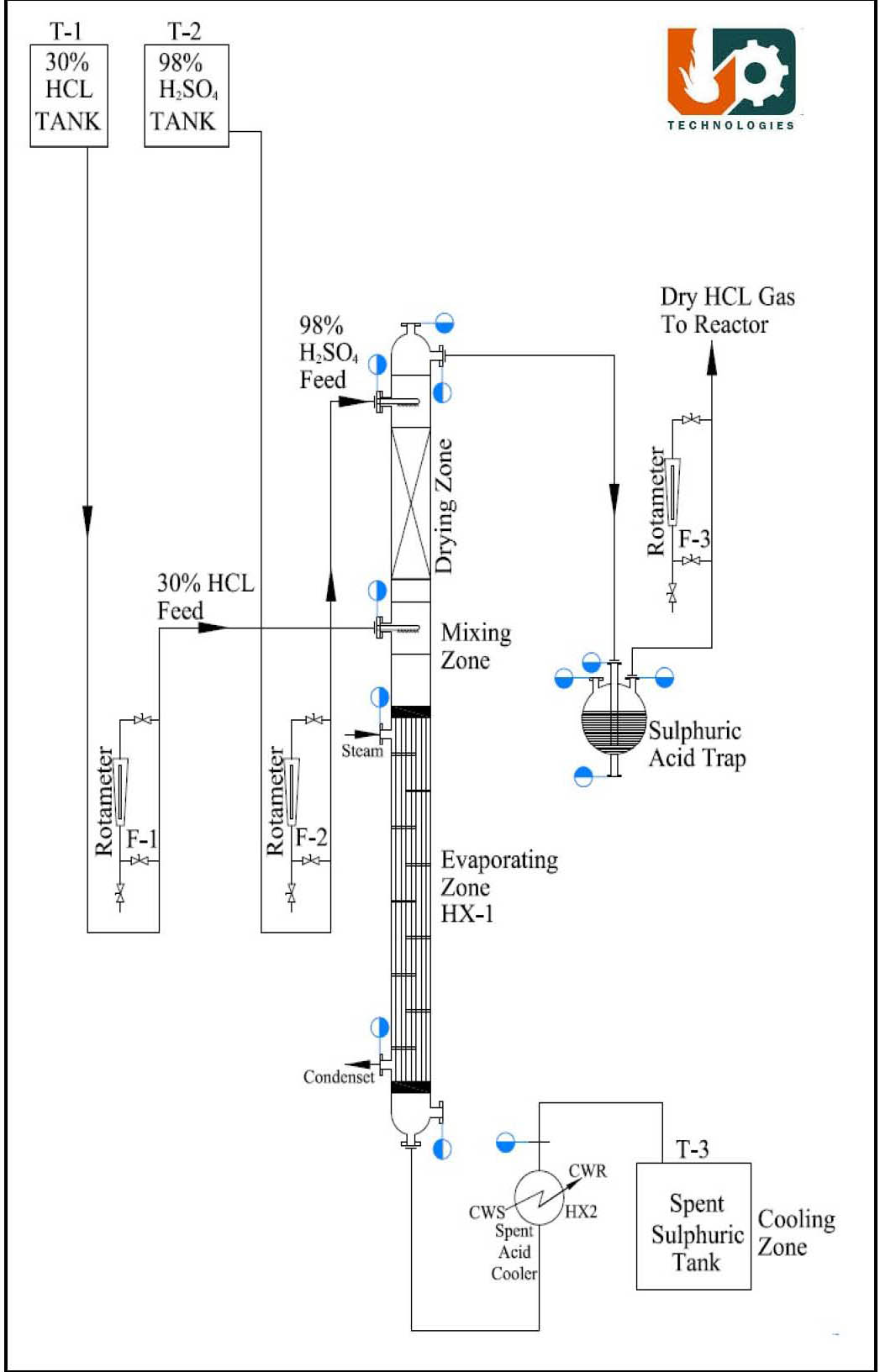

Metered quantities of HCl acid and CaCl2 solution pumps to stripping column. Due to this mixes in required quantities. Also, a steam heated re-boiler provided at the bottom supplies heat to keep the solution hot.

The effluent from the bottom of the column is a dilute acidic calcium chloride solution. So, this solution concentrates to the desired concentration in an evaporator. After concentration, a concentrated solution recycles in the Hydrogen chloride generator column.

The vapor leaving the Hydrogen chloride Generator condenses stage-wise with firstly, cooling water and secondly chilled brine as a coolant. Therefore this condensation helps to achieve dryness in HCl Gas. However, Brine can be used for better results and lower consumption of Sulfuric Acid in Trap

For further drying, HCl gas passes through a mist eliminator and washes out in sulfuric acid. As a result, Gas is completely dry.

After that, Gas leaves to the point of consumption.

SALIENT FEATURES:

- Designed Considering operation and maintenance problem

- A proven design that is a combination of different MOC most suitable for application

- Turn down ratio of 30%

- Simple operation makes system operation and maintenance Friendly(Less Pump and Instrumentation)

- ·Nearly zero Effluent system which makes the payback period fast over other systems. This is due to Higher raw Material costs and handling and neutralization costs of Effluents in other routes

- Supplied by an experienced team of Engineers in this field

Please visit the following related pages

https://www.linkedin.com/pulse/anhydrous-hcl-gas-generation-calcium-chloride-route-samir-shah/