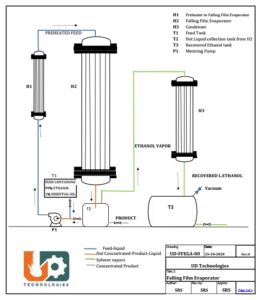

Falling Film Evaporator

UD Technologies are manufacturers of Glass Falling film evaporator .Falling Film Evaporator is essentially shell & tube heat exchanger. They applies for the evaporation of temperature sensitive substances and those tend to form useless residues by condensation or polymerization.

Size and Available Models :

Are available in Heat trasfer area from 2 Sq. Mt to 20 Sq. Mt. and From Diameter 4” to 12”.Larger sizes can be offered on request

Principle of Operation:

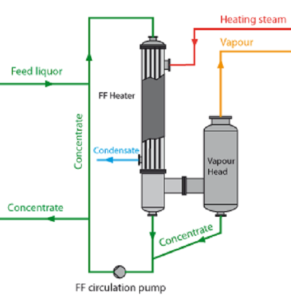

In falling film evaporators, liquid and vapors flow downwards in parallel flow. The liquid to be concentrated is preheated to boiling temperature if required. An even thin film enters the heating tubes via a distribution device in the head of the evaporator, flows downward at boiling temperature, and is partially evaporated.

The liquid to be evaporated is evenly distributed on the inner surface of a Glass tube. The liquid will flow downwards forming a thin film, from which the boiling/evaporation will take place because of the heat applied by the hot oil . . A number of tubes are built together side by side. At each end the tubes are fixed to tube plates, and finally the tube bundle is enclosed by a shell made either of steel or Glass depending upon the Hot oil pressure. The Hot oil is introduced through the shell. The space between the tubes is thus forming the heating section. The inner side of the glass tubes is called the boiling section. The concentrated liquid and the vapour leave the evaporator at the bottom part, enters the subsequent separator tangentially from where the concentrated liquid is discharged (usually by means of the pump) from the bottom and vapor leave the separator from top.

Advantages

Falling film evaporators can be operated with very low temperature differences between the heating media and the boiling liquid, and they also have very short product contact times, typically just a few seconds per pass. These characteristics make the falling film evaporator particularly suitable for heat-sensitive products, and it is today the most frequently used type of evaporator.

However, falling film evaporators are designed very carefully for each operating condition; sufficient wetting of the heating surface by liquid is extremely important for trouble-free operation of the plant. If the heating surfaces are not wetted sufficiently, dry patches and incrustations will occur; at worst, the heating tubes will be completely clogged.

Critical Design

The proper design of the liquid distribution system is critical to achieve full and even product wetting of the tubes. This is specially designed by ‘UD Technologies’.

Because of the low liquid holding volume in this type of unit, the falling film evaporator can be started up quickly and changed to cleaning mode or another product easily.

Falling film evaporators are highly responsive to alterations of parameters such as energy supply; vacuum, feed rate, concentrations, etc. When equipped with a well-designed automatic control system ,they can produce a very consistent concentrated product.

Selection Criteria referring to Vapor exit location

Flow of vapor and liquid may be either co-current, in which case vapor-liquid separation takes place at the bottom, or countercurrent (the liquid is withdrawn from the bottom and the vapor from the top). For co-current flow, the vapor shear-forces thin the liquid film, and yield higher heat-transfer coefficients. Moreover, since the vapor is in contact with the hottest liquid at the point of withdrawal, stripping is more efficient.

In countercurrent flow, shear forces increase the liquid-film thickness, and reduce the heat-transfer coefficient. If the vapor flow rate is high enough, it may lead to flooding of the tubes, with liquid carried upward beyond the point of injection, resulting in decreased performance and unstable operation. Countercurrent operation is used where it is necessary to evaporate a liquid at a low temperature under vacuum conditions, or where an inert gas (e.g., nitrogen or air) is injected into the tubes at the bottom of the unit to reduce the partial vapor pressure, and hence boiling point, of the liquid.

For other Options of Gentle Evaporation of Heat Sensitive solution

Large Scale Rotary Film Evaporator

Useful Information

[/vc_column_text]