Solvent losses in Rotary Film Evaporator

Rotary Film Evaporator is used for concentrating Heat sensitive Products (which are in Organic solvents)By Evaporation or Distillation. Distillation is a method of separation depending on the difference in volatility or Boiling Points of the mixture.

This is particularly useful if the temperatures required for fluid to boil at atmospheric pressures would be hot enough to damage sensitive molecules through polymerization or by thermal cracking. Or can degrade Heat Sensitive substances Particularly Organic Extract of Herbs in Rotary Film Evaporator

Vacuum distillation is used to lower the pressure above a liquid to less than its vapor pressure. This allows the most volatile liquids to be selectively boiled off and distilled.

We shall discuss the case of evaporation or distillation of herb extract in organic solvents or Water. As herb extracts are heat sensitive, It is commonly distilled in Rotary Film Evaporator or Wiped Film Evaporator. In extraction, generally, there is a single solvent. So it is to be evaporated in either Rotary Film Evaporator or Wiped Film Evaporator under vacuum

Depending on the availability of Coolant temperatures it is desired to Evaporate solvent with 20-30 deg C to boiling point temperature higher than coolant outlet temperature for efficient condensation and recovery. As Vacuum Source say –Vacuum Pump or Ejector selected for the lowest vacuum for Multipurpose application; frequently it happens that boiling points of solvents are higher than or nearby coolant outlet temperatures. This causes weak recovery of solvents and damage to vacuum Source and Environment

In the case of Rotary Film Evaporator; Product is high-value concentrate. But in many cases product is condensate. This results in huge monetary losses.

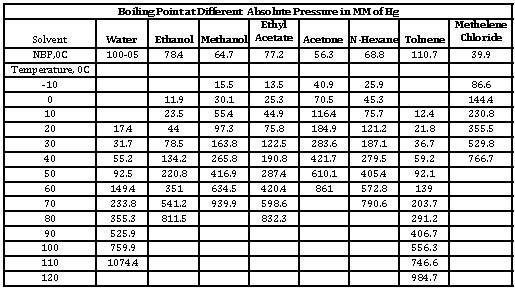

Please find Boiling points of different Pure solvents at different Absolute Pressures in MM of Hg. These values are calculated so it is nearby actual boiling point and of Pure solvents. To convert values in gauge vacuum, values to be subtracted from 760. Utility Temperatures in Research Labs or chemical Plant cannot be changed.

So Solution to this scene is to apply vacuum such that Solvent boils 20-30 deg above Coolant outlet temperature. It is possible with applying vacuum controller

Vacuum controllers are available which is designed for Rotary Evaporators and Reactors in Pilot plants with valve control logic. For the larger volume of Reactors, it can be made available with Proper design considering Process requirements

Vacuum control is required when High volatile solvents are to selectively boil off initially so that there shall be less impurity in Final Products

Vacuum Controllers have also available interlinked with Process parameters and time for a different application than Distillation

Please visit the following the link

http://udtechnologies.com/rotary-evaporator/

Please also visit another related article

https://www.linkedin.com/pulse/solvent-losses-batch-distillation-subsequent-vapors-how-samir-shah

Rotary Evaporator-Rotavapor-Rotary Film Evaporator

Please contact Samir Shah on [email protected] for more details

Rotary Evaporator-Rotavapor-Rotary Film Evaporator

Tag

Distillation, Evaporation, Evaporation of Heat Sensitive Materials, Automatic vacuum controller for Laboratory Rotary Evaporator, Vacuum control in large Reactors and distillation columns, Vacuum controllers, Vacuum Regulator, Large Scale Rotary Evaporator